Laser cutting technology has revolutionized the manufacturing industry, offering high precision and versatility for a wide range of applications. Whether in automotive production, aerospace engineering, or even artistic endeavors, laser cutting machines have become indispensable tools. In this article, we will explore the basic concepts behind laser cutting machines and delve into their applications in various industries.

Understanding Laser Cutting Technology

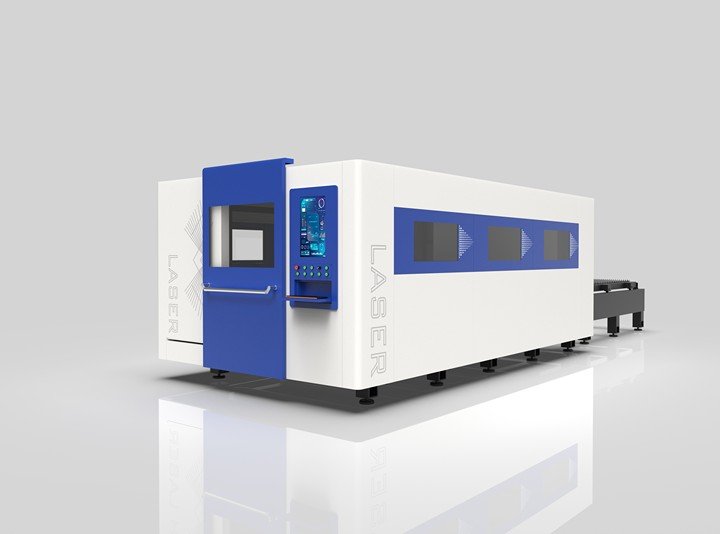

A laser cutting machine utilizes a focused laser beam to cut or engrave materials with incredible precision. The term “laser” stands for Light Amplification by Stimulated Emission of Radiation, which describes the process of creating a concentrated beam of light. This light is amplified and directed through optical fibers or mirrors onto the material being cut. As the laser beam strikes the surface of the material, it melts, burns, or vaporizes the material, depending on the settings.

The key advantage of laser cutting over traditional cutting methods lies in its ability to achieve high precision without physical contact. Unlike mechanical cutting methods, which can cause wear on the tools, laser cutting is non-contact and does not exert physical force on the material. This minimizes the risk of deformation and ensures cleaner cuts, particularly on thin materials.

Types of Laser Cutting Machines

Laser cutting machines come in various configurations, each designed to meet specific cutting needs. The most common types include:

Plate Cutting Machine

Plate cutting machines are designed to cut large, flat sheets of metal or other materials. These machines are often used in industries that require the cutting of large, flat parts with high accuracy. The laser is typically focused on a flat surface, and the cutting path is controlled by computer numerical control (CNC) systems. Plate cutting machines are highly efficient for cutting materials such as stainless steel, aluminum, copper, and carbon steel.

Single Table Laser Cutting Machine

A single table laser cutting machine features a single platform where the material is placed for cutting. The table is often equipped with a moving axis that allows the laser head to traverse the material along the designated cutting path. This type of machine is ideal for smaller production runs or jobs where the material size is limited. The single table setup makes the machine more compact and cost-effective, making it a popular choice for workshops or small businesses. While it may not be as efficient for large-scale manufacturing as multi-table machines, it offers excellent precision for smaller, detailed cuts.

Pipe Cutting Machine

Pipe cutting machines are specifically designed to cut pipes and tubes with high accuracy. These machines can handle materials of various diameters, from small pipes used in plumbing to large industrial pipes found in construction and energy sectors. Pipe cutting laser machines employ a rotating system, which allows the laser to cut along the circumference of the pipe. This is ideal for applications that require precise cuts on tubular materials, such as for exhaust systems, fluid conduits, or structural supports.

Applications of Laser Cutting Machines

Laser cutting machines have a broad range of applications across several industries, due to their versatility, speed, and precision. Let’s take a closer look at how these machines are used in different sectors.

Manufacturing and Metalworking

Laser cutting is extensively used in the manufacturing industry, particularly for plate cutting machines. These machines can efficiently cut metal sheets for automotive, construction, and electronics applications. The precision of laser cutting allows manufacturers to create complex designs and intricate details that would be difficult to achieve with traditional cutting tools. Additionally, the lack of physical contact reduces tool wear, which results in lower maintenance costs and improved productivity.

Automotive Industry

In the automotive industry, laser cutting machines are employed to cut various parts with high precision. The single table laser cutting machine is particularly useful for smaller, detailed parts used in car bodies, such as brackets, panels, and trim. Laser cutting provides the necessary accuracy to ensure that each part fits perfectly during assembly, reducing the chances of errors in the manufacturing process. Moreover, laser cutting also reduces the amount of heat generated during cutting, which minimizes the risk of material warping or distortion.

Aerospace and Defense

The aerospace industry demands high-precision parts, especially when it comes to cutting materials used in aircraft structures and components. Laser cutting is ideal for cutting complex shapes out of high-strength materials such as titanium, aluminum, and other alloys. The ability to make intricate cuts without affecting the structural integrity of the material is one of the key reasons why laser cutting is used extensively in aerospace and defense sectors. In particular, pipe cutting machines play a vital role in the fabrication of components like exhaust systems and air ducts in aircraft.

Medical Device Manufacturing

Laser cutting also finds significant application in the medical device manufacturing sector. High-precision cuts are required to create devices such as surgical instruments, implants, and diagnostic tools. Laser cutting offers an accurate and efficient way to create these devices, ensuring that each component is manufactured to exact specifications. The technology is particularly valuable when working with delicate materials like plastics or thin metals, which are commonly used in medical applications.

Art and Design

Outside of industrial applications, laser cutting is also used in **art and design**. Artists and designers use laser cutting machines to create intricate patterns, custom designs, and detailed engravings in materials such as wood, acrylic, and paper. The flexibility of the technology allows for high creativity and complexity, enabling designers to produce unique items like custom signs, decorations, and artwork. For this purpose, a **single table laser cutting machine** is typically sufficient, as it allows for precise cuts on small to medium-sized materials.

Advantages of Laser Cutting Machines

Laser cutting offers several advantages over traditional cutting methods, making it an increasingly popular choice for manufacturers across various sectors.

Precision and Accuracy:

Laser cutting provides exceptional accuracy, capable of achieving fine cuts with tight tolerances. This makes it ideal for applications that require detailed and intricate designs.

No Contact with Material:

Since the laser beam doesn’t physically touch the material, there’s no wear on the cutting tools. This results in less maintenance and longer machine lifespan.

Versatility:

Laser cutting can be used on a variety of materials, including metals, plastics, wood, glass, and even fabrics, providing flexibility for different applications.

peed and Efficiency:

Laser cutting machines can operate at high speeds without compromising quality, making them highly efficient for both small and large production runs.

Conclusion

Laser cutting machines, including plate cutting machines, single table laser cutting machines, and pipe cutting machines, offer precise, efficient, and versatile solutions for a wide range of industries. Their ability to cut through various materials with exceptional accuracy makes them indispensable tools in manufacturing, aerospace, medical device production, and even artistic design. With ongoing advancements in laser technology, these machines will continue to drive innovation and improve production processes across numerous sectors.

Whether you’re in need of detailed parts for the automotive industry or custom designs for a creative project, a laser cutting machine provides the tools necessary to achieve high-quality results quickly and efficiently.